Vinyl Record Terminology

Music is a universal language, and in an effort to make sure we're all speaking the same vinyl language, we wanted to create a glossary of terms from a team of people here at Women in Vinyl who work in the vinyl manufacturing industry. Check out the below glossary to enhance your trivia knowledge or be able to know exactly what you're asking for when ordering your next vinyl release.

Glossary of Terms

Acetate - A lacquer that has not been electroplated to create stampers. These discs have a soft surface and are easily damaged. However, they do feature cut grooves, so they are playable on a turntable. See also: Dubplate, Reference Lacquer, Test Acetate, and Transcription Disc

Bone Music - Russian bootleg lathe cut recordings after the second world war, cut into recycled x-ray film.

Carbon Black - Colorant additive used to create black vinyl that also adds durability and strength to the PVC mix.

Center Hole - The hole in the center of your record that sits on the spindle of your turntable. Formed by a center pin punching through the vinyl puck.

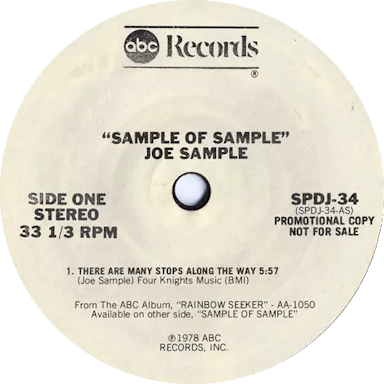

Center Label - The circular label appearing on each side of a pressed record displaying images, sides, RPM, song titles, and other recording information. A common misconception is that these are stickers, but for pressed records they are actually pressed into the puck.

Colorants - Color additives used to create an endless rainbow of color and design options for record manufacturing.

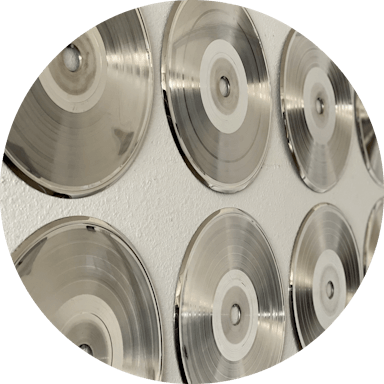

Compact Discs (CDs) - Polycarbonate plastic discs with a reflective metallic digital data storage layer covered with an acrylic plastic coating that is read with a laser.

Deadwax - The un-engraved area near the center label of a record. Referred to as "dead" because it contains no sound.

Deadwax Etching - The markings or inscriptions found in the blank area (see "deadwax") near the center of a vinyl record, outside the grooves. These can include the catalog number, mastering engineer’s initials, production notes providing additional information about the record's production or messages etched by the engineer requested by the artist.

Debossed - Recessed ornamental pattern or image design on the surface of an object. Meaning the grooves at this stage are below the surface of the stamper, like on your records at home.

Digital Audio Workstation (DAW) - Electronic components and/or software used to record, edit and produce audio files.

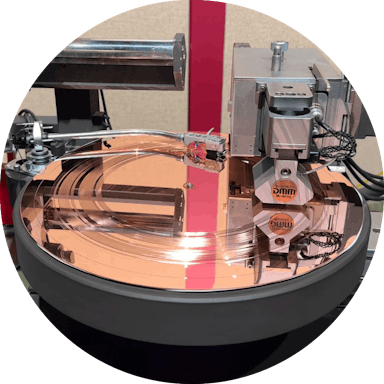

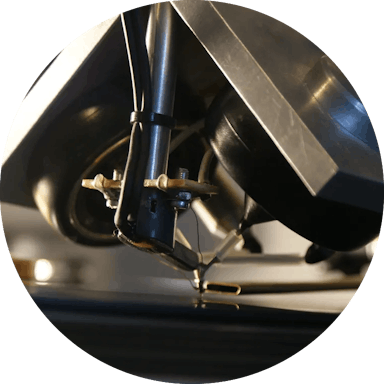

Direct Metal Mastering (DMM) - Process for transferring recorded sound that bypasses lacquer discs, relying on a copper-coated disc instead. A lathe engraves the audio directly into the copper disc. The copper disc goes right from the cutting process to plating, skipping the first silver spray in the electroplating process.

Dubplate - A lacquer that has not been electroplated to create stampers. These discs have a soft surface and are easily damaged. However, they do feature cut grooves, so they are playable on a turntable. See also: Acetate, Reference Lacquer, Test Acetate, and Transcription Disc.

Electroforming - A distinction from the generalized electroplating process, which coats one metal with another, electroforming creates a separate part or piece at the end of the process. See also: electroplating.

Electroplating - A process that coats a metal object with another metal using an electrical current passed through a chemical solution. This process is used to create a stamper in the record manufacturing process.

Embossed - Raised ornamental pattern or image design on the surface of an object. Meaning the grooves at this stage are raised from the surface of the stamper rather than etched below the surface like on your records at home.

Endless Loop - A specially designed groove that continuously repeats a section of audio when played. The groove is engineered in a way that the stylus keeps cycling through the same part of the track without reaching the end, making it ideal for background music or sound effects that need to play indefinitely.

Extended Play (EP) - A record containing more tracks than a single but fewer than a full-length album. Introduced by RCA Victor as a 7-inch record playing at 45 RPM with about 7 mins of (optimal) sound on each side.

Father Plate - The first nickel plate produced in the electroplating process which is a reverse copy of the original lacquer cut featuring debossed grooves, also referred to as a master plate. Also see: Electroplating Process - one-step

Flash - The excess PVC that spills over the edges of a stamper on a record press during the pressing process. Flash is trimmed from the outer edge of a record before it is released from the press.

Galvanics - Generation and use of electrical current generated by a chemical reaction.

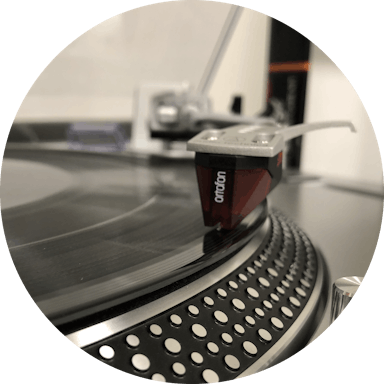

Gramophone - Synonym for Phonograph, Record Player, and Turntable

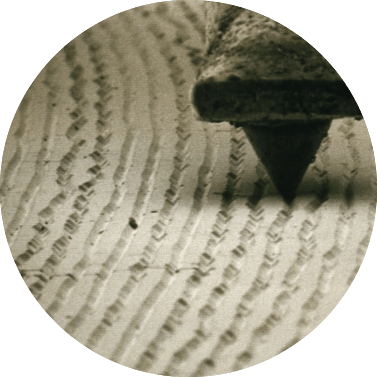

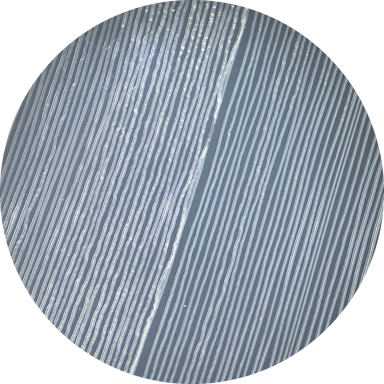

Groove - The spiral track etched into the surface of a vinyl record that contains the audio information. As the stylus (needle) moves along the groove, it detects the tiny variations in the track's walls, translating them into sound. The groove is precisely designed to carry the vibrations that produce music, with its shape and width varying depending on factors like audio frequency and pressing quality.

Heat Stabilizers - An additive in the special PVC mix for record making. These additives help to make the overall compound more robust and neutralize hydrogen chloride gas.

Inner Sleeves - The protective paper or plastic sleeve that holds a vinyl record inside its outer jacket. It helps prevent scratches, dust, and other damage to the record's surface while not in use, often featuring additional details like artwork, credits, or album information.

Jacket - The the outer packaging for a vinyl record, typically made of cardboard, that holds the album and its inner sleeve. It can come in various styles, such as a single-pocket (open on one side), gatefold (with two panels that open), or tip-on (with the artwork glued onto the jacket), and may include features like embossed details, special finishes, or inserts for added presentation.

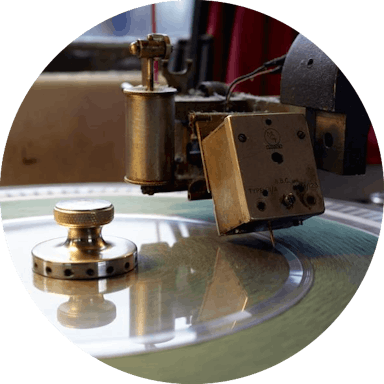

Lacquer - An aluminum disc coated in a thick layer of nitrocellulose with a highly flammable mirror-like sheen. The first tangible element in the record manufacturing process, mastering engineers cut sound into a spiral-shaped groove flowing from the outer edge toward the center label.

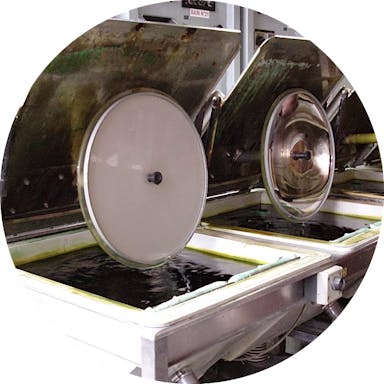

Lathe - A machine used to cut or engrave grooves into a vinyl disc, typically during the mastering process. It carves the audio data into the surface of the disc, creating a master copy from which vinyl records will be pressed.

Lathe Cut Disc - A playable plastic record cut one at a time using a special rotating machine called a lathe. Used mostly for small quantity, collectible sound recordings.

Long Play (LP) - A record containing more tracks than an Extended Play (EP). Introduced by Columbia in 1948, showcase the "microgroove" technology play at 33 1/3 RPM. LPs are 12 inches in diameter and provide about 21 mins of (optimal) sound on each side.

Lubricants - An additive in the special PVC mix for record making. This additive assists the puck of PVC to spread more evenly and consistently across the surface of the stamper during production.

Master Plate - The first nickel plate produced in the electroplating process which is a reverse copy of the original lacquer cut featuring debossed grooves. See also: Father Plate, Record Press Process - one-step

Mastering - Final step in the music production process, where the mixed tracks are polished and optimized for distribution. It involves adjusting levels, EQ, compression, and ensuring consistency across the album or tracks. The goal is to enhance the overall sound, balance audio elements, and prepare the recordings for various formats (digital, vinyl, CD) while maintaining the artist's intended vision.

Microgroove Record - Innovation in record technology created by Peter Goldmark, allowing for longer durations of music to be cut into each side of the recorded disc. The grooves were read using a special Microgroove stylus (maximum tip radius 0.001 in or 25 μm) and provided 21 (optimal) playback time per side spinning at 33 1/3 RPMs.

Mono - Sound recorded using one audio channel, intended to be heard as if it is coming from one position. Also known as Monaural or monophonic sound. Recordings made before 1958 are Monaural.

Mono Embossing - Modern lathe cut method of scratching the grooves into the plastic with the stylus. Final products tend to have lower fidelity, lower volume, and shallower grooves.

Mother Plate - A copy of the master or father plate made by repeating the electroplating process using the father plate as a base. The Mother plate is a positive nickel casting that can be electroplated multiple times to create additional stampers usable on a record press. Each mother can produce approximately ten stampers. The grooves of a mother are embossed and are playable on a regular turntable. See also: Record Press Process - two-step.

Mould - The "holder" that stampers are placed onto when put inside the record press. They have channels inside them for steam and cold water to circulate through in order to heat and cool the PVC.

Noise Floor - The total sum of unwanted signals in audio; this is the lowest threshold of signal that is detectable in a recording. A lower noise floor means there is less undesirable or ambient noise in the playback of a recording, allowing a broader range of low sounds to be audible. If you hear someone say a recording is 'dead quiet,' this means it has a very low noise floor and sounds very clear.

Nonfill - A production error occurs when the PVC does not get hot enough in the record press, causing the material to inadequately fill the grooves on a stamper's surface.

Obi - A printed paper or cardboard strip attached around the spine (obi spine) or looped around the vinyl jacket (obi wrap or belly band), typically found on Japanese releases. It displays information such as the album title, artist, track list, and promotional details, and is valued by collectors as part of the original packaging.

Overage - Refers to extra items produced or provided beyond the original order to account for errors, defects, or waste. It ensures the required quantity is met even if some are unusable within an agreed upon margin.

Phonograph - Synonym for Gramophone, Record Player, and Turntable.

Plasticizers - Chemicals added to PVC to make the mix more pliable, resulting in a more flexible and more durable final product.

Polyvinyl Acetate (PVA) - One of the first additives mixed with PVC to create the special vinyl record blend.

Polyvinyl chloride (PVC) - The foundational component of the vinyl record plastic mix. In its pure form, it is translucent white, and somewhat brittle.

Pre-echo - The phenomenon where an echo or “print-through” in a recording, mechanically induced by a manufacturing fault, is heard before the sound causing it when the recording is played. Caused by an overheated cutting stylus on the cutting lathe.

Pre-plate - Step in the electroplating process after silvering where the silvered lacquer is briefly placed into an electroplating bath of a lower temperature and lower amperage and coats the silver with an initial thin layer of nickel. This plating bath helps acclimate the lacquer to the electroplating process. Helps eliminate pre-echo in final stamper plates. See also: pre-echo.

Pressing Overage - When extra copies beyond the original order are pressed to account for defects, quality control issues, or losses during production. 10% overage is industry standard and added to ensure the customer receives the exact number of usable records, compensating for any that may not meet quality standards.

Pressing Unders - This occurs when fewer copies are produced than ordered, often due to production errors, material shortages, or issues during the pressing process. This results in a shortfall, meaning the customer receives fewer records than requested and a credit for not receiving the amount ordered, and is within tolerance to not put the project back on the machine to produce more. Industry standard is +/- 10%.

Print Overage - Refers to the extra copies of printed material produced beyond the original order. This is typically done as a safeguard to account for potential issues during the printing process, like defects, damage, or misprints. The overage ensures that the customer receives the exact number of usable copies they requested. Industry standard is +/- 10%.

Print Unders - Refers to a situation where fewer copies are produced than ordered, typically due to errors, issues with the printing process, or material shortages. It means the printed quantity falls short of the requested amount, but is within tolerance to not put the project back on the machine to produce more. Industry standard is +/- 10%.

Proofing - The process of "proofreading" or looking over all final printed materials for errors in text or image assets.

Puck - The thick circle-shaped biscuit of vinyl mixture placed between two stampers on a record press is heated under immense pressure to flatten and fill all the grooves and create a record.

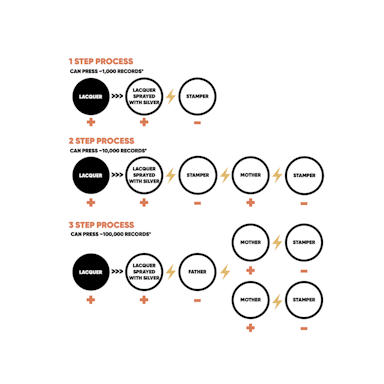

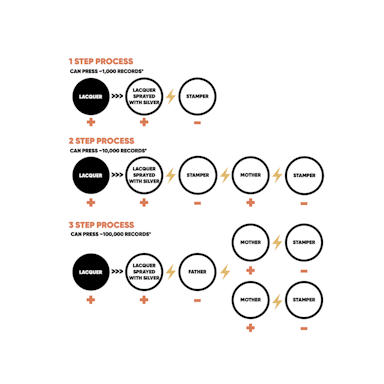

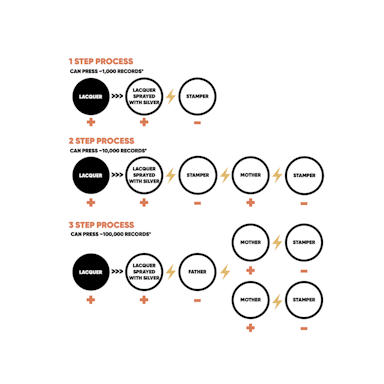

Electroplating Process - one-step - The electroplating process that goes from cut lacquer disc through one step of electroplating to create a single master stamper. That master stamper or father plate is used on the record press to stamp out discs. The term "one-step" refers to there being only one step from the original cut lacquer to the stamper. This technique is best for small runs of less than 500 copies. Also see: Father plate

Electroplating Process - two-step - The electroplating process that relies on two steps of electroplating after the lacquer disc is cut by the mastering engineer. The first step of electroplating creates the father or master plate. A second round of electroplating creates a "mother" plate which can be used to make ten father stampers. The first father is used as a stamper during the two-step process. This process is best used on runs of less than 10,000 copies.

Electroplating Process - three-step - The electroplating process best suited for large pressing runs of more than 10,000 copies. The three-step process involves setting aside both the first father plate and the first mother plate. These original plates are used to generate new additional copies (stampers) of its counterpart without requiring a new lacquer cut.

Record Speeds - 33 1/3 - Rate of speed in which thirty-three and one-third rotations of a turntable platter are completed per 60-second duration. This is the speed best suited for playing microgroove LPs and is currently the standard for most 10 and 12-inch albums.

Record Speeds - 45 - Rate of speed in which forty-five total rotations of a turntable platter are completed per 60-second duration. This speed is best suited for EPs pressed on 7-inch records, but some other specialty-pressed records utilize this speed as well.

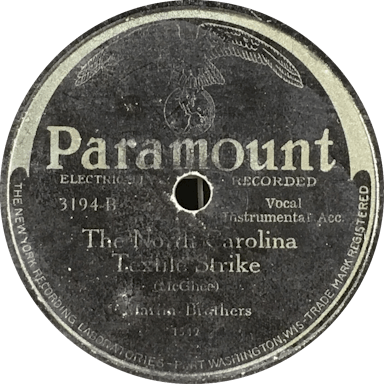

Record Speeds - 78 - Rate of speed in which seventy-eight total rotations of a turntable platter are completed per 60-second duration. This is the standard for most shellac resin recordings created up through the first half of the 1900s. These recordings hold approximately five minutes of sound per side.

Rectifier - An electronic power supply device that converts available AC (alternating current) electricity to DC (direct current) electricity.

Reference Lacquer - A lacquer that has not been electroplated to create stampers. These discs have a soft surface and are easily damaged. However, they do feature cut grooves, so they are playable on a turntable. See also: Acetate, Dubplate, Test Acetate, and Transcription Disc.

Release Date - The anticipated date that a record is to be released.

Rotations Per Minute (RPM) - The measure of rotations. In terms of making records method of identifying the speed at which a turntable platter spins. Also known as Revolutions Per Minute.

Runout Groove - The circular track at the end of a vinyl record, just before the deadwas and label. It serves as a buffer zone where the stylus slows down and eventually lifts off the record, signaling the end of the side.

Silvering - The first coating in the electroplating process of record stamper creation. A thin layer of silver sprayed onto a deep-cleaned lacquer surface. This layer of silver acts as the base layer for growing the nickel plating during the electroplating bath. See also: electroplating, lacquer, stamper.

Stamper - The plate used on a record press to form each side of a record. The hot vinyl puck is pressed between an A-side stamper and a B-side stamper to produce a two-sided recording.

Stereo - Sound recorded using two audio channels, intended to be heard as if it is coming from multiple directions. Also known as stereophonic sound. Records made during the 1960s can be either Stereo or Mono, but stereo eclipsed mono, becoming the dominant format in audio entertainment by 1968.

Stereo Diamond - Modern lathe cut method of cutting the grooves into the plastic with a cutting stylus. Final products tend to have a higher fidelity cut with a deeper groove.

Stitching - A production error that occurs when the pressed PVC is cooled down too far, creating what looks like tiny lines or “stitches” on the surface of the record, creating an audible repetitive tearing sound.

Street Date - The date that a physical product will be available to consumers in stores.

Test Acetate - A lacquer that has not been electroplated to create stampers. These discs have a soft surface and are easily damaged. However, they do feature cut grooves, so they are playable on a turntable. See also: Acetate, Dubplate, Reference Lacquer, and Transcription Disc.

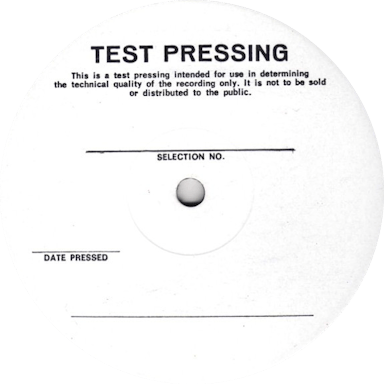

Test Pressings - The first records made from a set of stampers on a record press. These discs are reviewed by Quality Control specialists at the record pressing plant and sent to the artists and or labels for final approval before the full order is fulfilled by the plant.

Transcription Disc - A lacquer that has not been electroplated to create stampers. These discs have a soft surface and are easily damaged. However, they do feature cut grooves, so they are playable on a turntable. See also: Acetate, Dubplate, Reference Lacquer, and Test Acetate.

Vinyl Broker - This is a middle entity that works as a bridge between artists or labels and the pressing plant to handle the ordering and logistics of the manufacturing process.

Zoetrope - A special design where a series of images or patterns laid out at 30 frames per second so that when the record spins the the images appear to animate, making it an early form of motion picture technology.

Want more? Become a Friend of Women in Vinyl member today!